-

2001

Production began on November 6 in a 2,000 m² space.

-

2002

Major investment in SMT equipment.

-

2003

Initiation of ISO 9001:2000 certification.

-

2004

Implementation of an information system for production management

-

2005

Workspace expanded to 3,000 m² and ISO 9001:2000 certification

-

2006

Introduction of coating and Burn-In technologies

-

2008

Implementation of an efficient ERP system for integrated management

-

2009

Expansion of the SMT department with the addition of 4 CMS lines

-

2010

Creation of a Procurement Department, expansion of Burn-In testing facilities and Test department, and ISO 9001:2008 certification.

-

2011

Integration of new technologies, including selective soldering and mobile probe in-situ testing (Fly Probe).

-

2012

Enlargement of administrative facilities.

-

2013

Implementation of an MSL component management system.

-

2015

Expansion of the THT department.

-

2016 - 2018

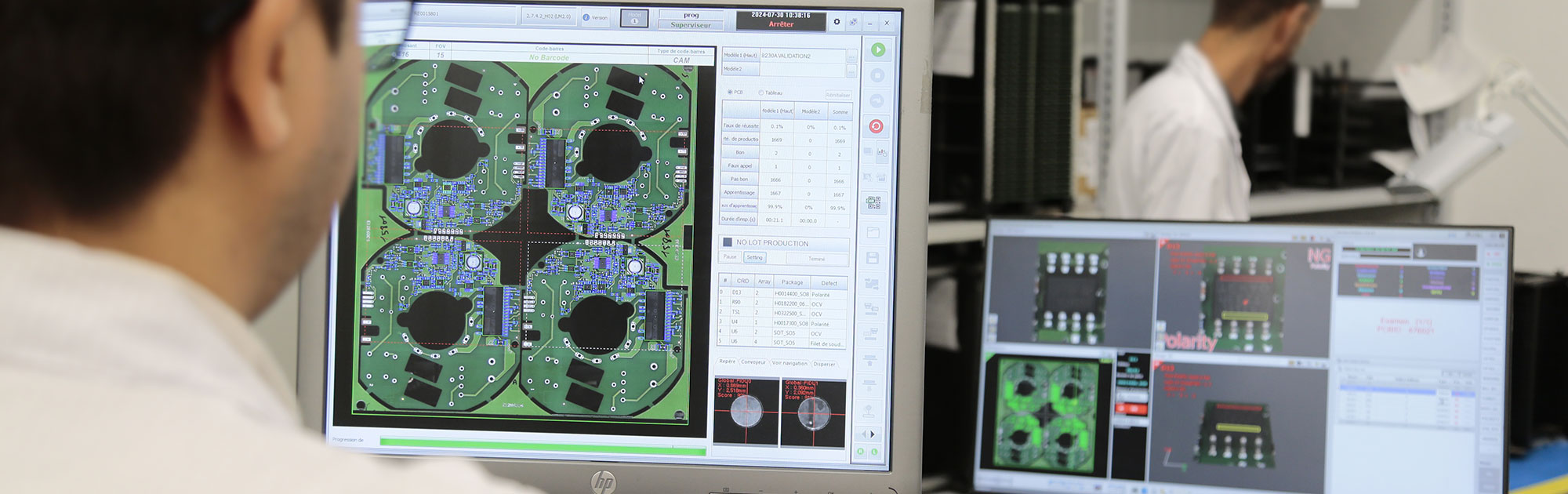

Addition of three CMS lines with a capacity of 50,000 components per hour each, enhancement of the AOI department with a 3D inspection machine, and ISO 9001:2015 certification.

-

2019

Addition of a CMS line with a capacity of 50,000 components per hour, installation of a wave soldering machine and an X-ray inspection machine.

-

2020

Adaptation to the COVID-19 crisis with adjustments in supply chain, production planning, order management, and workforce management in compliance with government regulations.

-

2021

Addition of two CMS lines with a capacity of 50,000 components per hour each, integration of a Flying Probe 4050 test machine, laser engraving and topography, and the TOWERMARK LX G laser engraving machine.

-

2022

Addition of a CMS line with a capacity of 60,000 components per hour, reinforcement of AOI and SMT departments with 3D inspection machines, particularly for solder paste control.

-

2023

Installation of a new wave soldering machine.

-

2024

Expansion of premises for finished products